Marshalling machine

Product Description

A marshalling machine is a specialized equipment used in industrial and logistics operations to efficiently sort, organize, and move various items, such as packages, containers, and pallets. It is designed to streamline the process of marshalling or arranging items based on specific criteria, such as destination, size, weight, or type, in order to optimize workflow and increase productivity.

Product Function

The primary function of a marshalling machine is to automate the sorting and arrangement of items. It utilizes advanced technologies, such as barcode scanning, RFID (Radio Frequency Identification), and computerized systems, to identify, track, and categorize items accurately and efficiently. The machine can be programmed to follow predefined rules and algorithms to determine the appropriate destination or location for each item.

Product Application

Marshalling machines are widely used in various industries, including e-commerce, logistics, warehouses, distribution centers, manufacturing facilities, and postal services. They play a crucial role in optimizing inventory management, order fulfillment, and supply chain operations. These machines can handle a wide range of items, from small packages to large containers, making them versatile and adaptable to different application scenarios.

Product Quality Control

Marshalling machines undergo rigorous quality control measures to ensure their reliability, accuracy, and durability. They are designed and manufactured according to industry standards and regulations. Quality control processes include thorough testing of the machine's mechanical components, electrical systems, software functionality, and overall performance. Regular maintenance and inspections are also performed to keep the machine in optimal working condition.

Product Stability

Marshalling machines are designed to provide stability and robustness in demanding industrial environments. They are built with high-quality materials and components that can withstand heavy usage and harsh operating conditions. The machines are engineered to have a stable and sturdy structure, ensuring smooth and precise movement of items during the marshalling process.

Product Safety

Safety is a top priority when it comes to marshalling machines. These machines are equipped with various safety features, such as emergency stop buttons, safety sensors, protective barriers, and alarms. Additionally, operators are provided with comprehensive training on machine operation and safety procedures to minimize the risk of accidents or injuries.

product_safety

product description

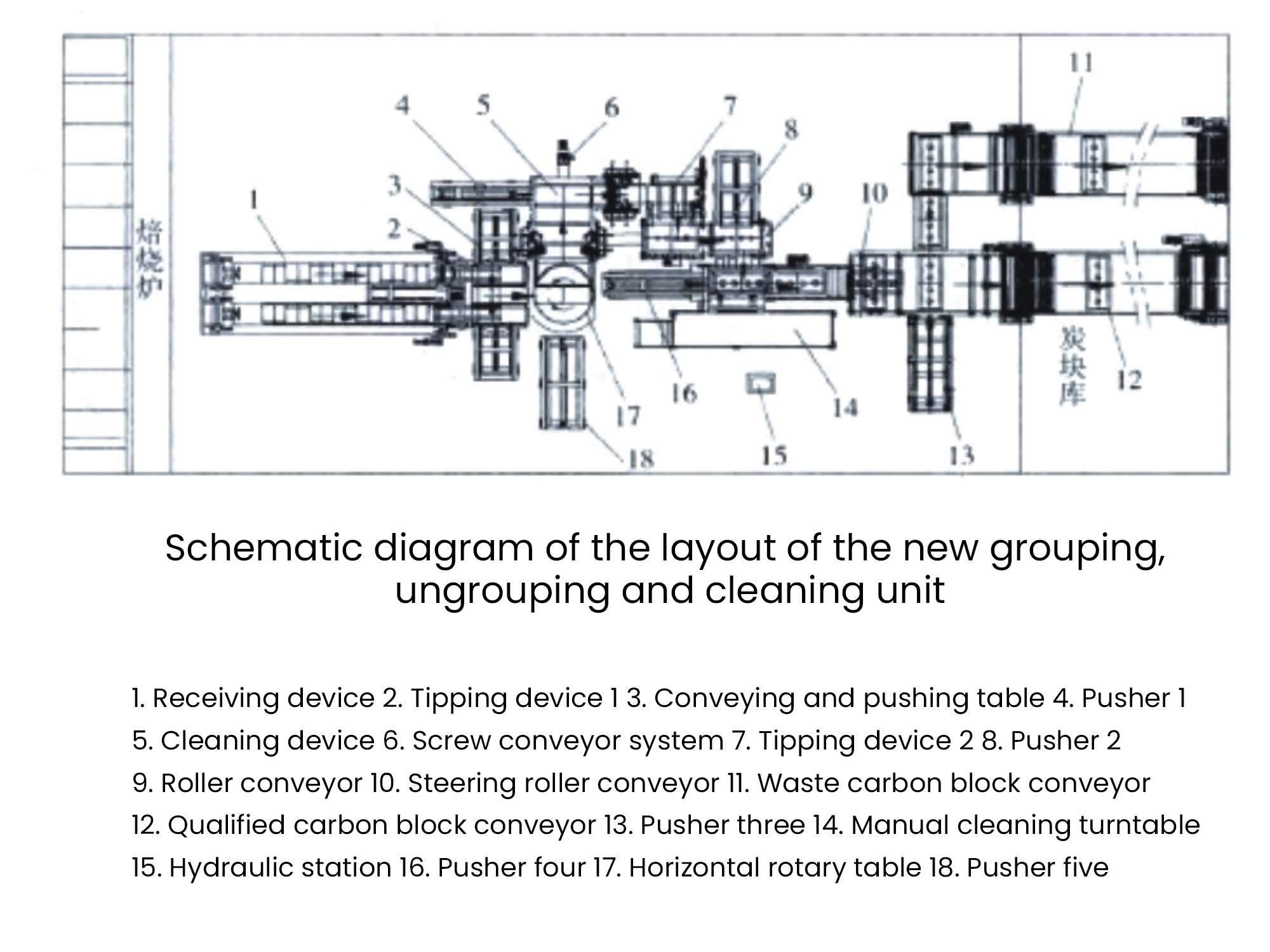

1. Product use description: The new grouping, ungrouping and cleaning machine is one of the necessary equipment for manufacturing prebaked anodes. In the roasting workshop, the roasted carbon blocks are divided into blocks and their surfaces are cleaned to improve work efficiency and reduce Environmental pollution, reducing workers' labor intensity (avoiding the risk of workers' burns, crushing injuries, silicosis and other work-related injuries). Currently, due to market demand, there are more and more types of carbon blocks in carbon factories, which brings huge difficulties to the cleaning of carbon blocks. Our company uses the connecting rod principle to successfully develop a unit that can adapt to various specifications of carbon blocks.

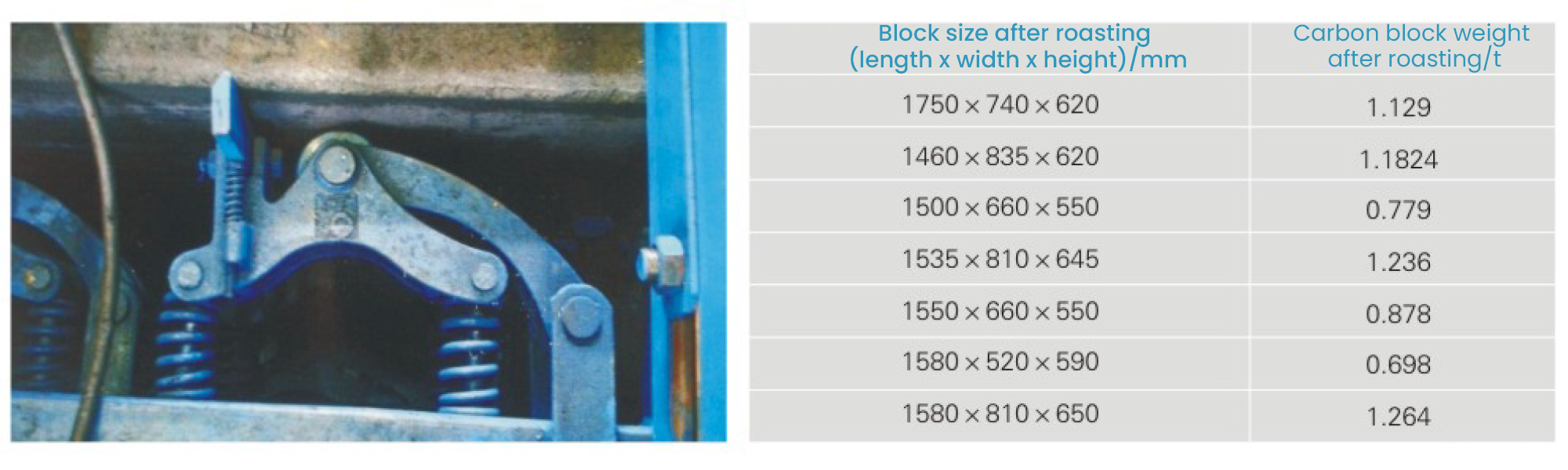

2. Product requirements: The new grouping, ungrouping, and cleaning machine unit requires automatic segmentation, cleaning, transportation, and grouping of roasted carbon blocks (see Table 1)

3. Product composition, layout and process flow: The new grouping, ungrouping and cleaning machine mainly consists of a receiving device, a tipping device, a push conveyor table, a horizontal rotary table, a cleaning device, a pusher, a cross steering conveyor, a qualified carbon It consists of block conveyor, waste block conveyor, manual cleaning turntable, hydraulic system and PLC electronic control system.

4. Product core design: Our company's products can effectively clean the surface of carbon blocks of various specifications. The core technology comes from the new scraping tool design and new tool layout. The company uses three-dimensional image technology to design the components from the tool's support and rotating arm. , tool holder, link mechanism, spring and other main structures are simulated for scraping, and through force calculation and dust collection system improvement, high scraping efficiency and cleaning quality are achieved, filling the gap in this field.

OUR FACTORY