Clamp Crane

Introduction: The clamp crane is a special equipment for the pre-baked anode workshop. The whole machine adopts PLC control, frequency conversion speed regulation and other configurations. It has been widely used in major carbon factories across the country and has reached the international advanced level. It has greatly improved the harsh working environment and reduced the labor intensity of workers.

Product Description

A clamp crane is a versatile lifting device specifically designed for gripping and lifting heavy loads securely. It consists of a sturdy frame with a hydraulic or mechanical clamp mechanism attached to it. The clamp crane is commonly used in various industries such as construction, manufacturing, and logistics to handle and transport bulky and heavy materials.

Product Function

The main function of a clamp crane is to securely hold and lift heavy loads. It features a powerful clamp mechanism that can grip objects of different shapes and sizes, providing a secure and stable lift. The clamp can be adjusted to accommodate various materials, including steel beams, pipes, concrete blocks, and wooden pallets.

Product Application

The clamp crane has a wide range of applications across different industries. In construction, it is commonly used for lifting and placing steel beams during building construction. In manufacturing, it is used for handling heavy machinery components or transporting large and bulky materials. In logistics, it is utilized for loading and unloading cargo containers or moving heavy items in warehouses.

Product Quality Control

Our clamp crane undergoes rigorous quality control measures to ensure its reliability and durability. Each unit is carefully inspected and tested for its performance, strength, and safety features. We adhere to international standards and guidelines to deliver a high-quality product that meets the demands of our customers.

Product Stability

The clamp crane is designed for optimal stability during lifting operations. It is equipped with a robust base and a counterweight system to prevent tipping or instability. The clamp mechanism is engineered to provide a secure grip on the load, minimizing the risk of slippage or accidents.

Product Safety

Safety is our top priority, and our clamp crane is designed with several safety features. It includes overload protection to prevent the crane from lifting beyond its capacity. The clamp mechanism is equipped with a safety lock to ensure that the load remains securely clamped during lifting. Additionally, the crane is fitted with emergency stop buttons and warning alarms to alert operators in case of any potential hazards.

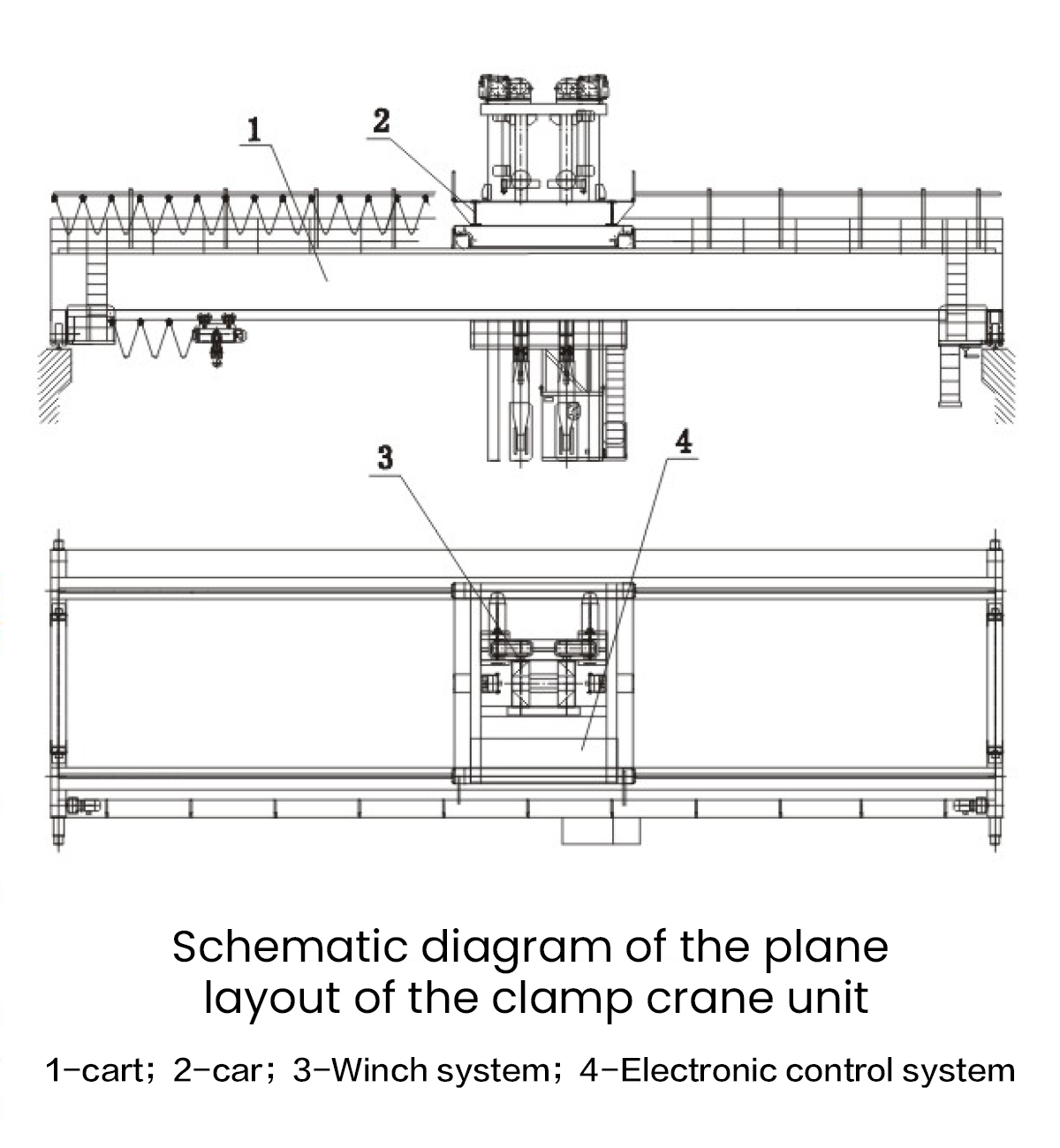

The clamp crane is a special equipment for the pre-baked anode workshop. Its main process operations:

1. Use clamps to transport the carbon blocks back and forth between the grouping/ungrouping.

2. Use the clamps to load the carbon blocks into/out of the roasting furnace kang.

3. There is an electric hoist under the bridge to assist in lifting far.

The whole machine adopts PLC control, frequency conversion speed regulation and other configurations. It has been widely used in major carbon factories across the country and has reached the international advanced level. It has greatly improved the harsh working environment and reduced the labor intensity of workers.

| Structure | Ltemized name | Unit | Parameter |

| Complete vehicle | Total weight | t | 90-150 |

| Working level | A6-A8 | ||

| Total installed power | kw | 110-130 | |

| Cart | Running speed | m/min | 5-50 |

| Speed mode | Frequency conversion | ||

| Working level | M6-M8 | ||

| Span | m | 22.5-36 | |

| Car | Running speed | m/min | 3-30 |

| Speed mode | Frequency conversion | ||

| Working level | M6-M8 | ||

| Hoist mechanism | Lifting speed | m/min | 1-10 |

| Speed mode | Frequency conversion | ||

| Working level | M6-M8 | ||

| Lifting capacity of single clamp (excluding clamp) | t | 6-10 | |

| Clamp lifting stroke | m | 7-9 | |

| Electric hoist | Lifting capacity | t | 5-10 |

| Lifting speed | m/min | 7-8 | |

| Running speed | m/min | 20 |

OUR FACTORY