Roasting Multi-Function Crane

1: Use clamps to transport the carbon blocks back and forth between organizing/unassembling.

2: Use clamps to load/exit the carbon blocks into the roasting furnace kang

3: Use the discharge pipe to fill the filling material into the furnace pit.

4: Use the suction pipe to suck out the high-temperature filling material from the furnace pit.

5: There is an electric hoist under the bridge to assist in lifting.

Product Description

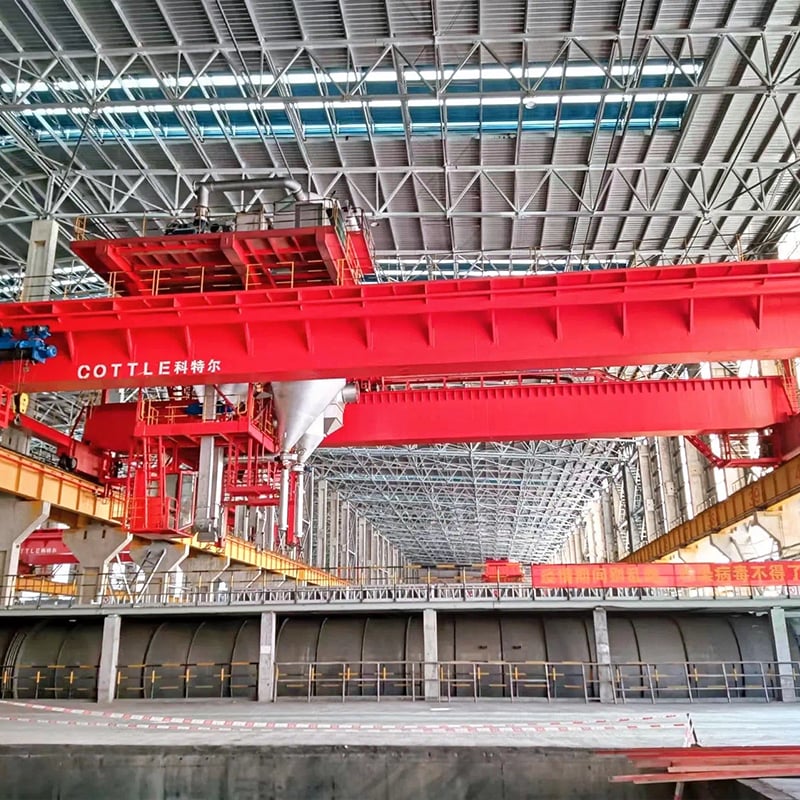

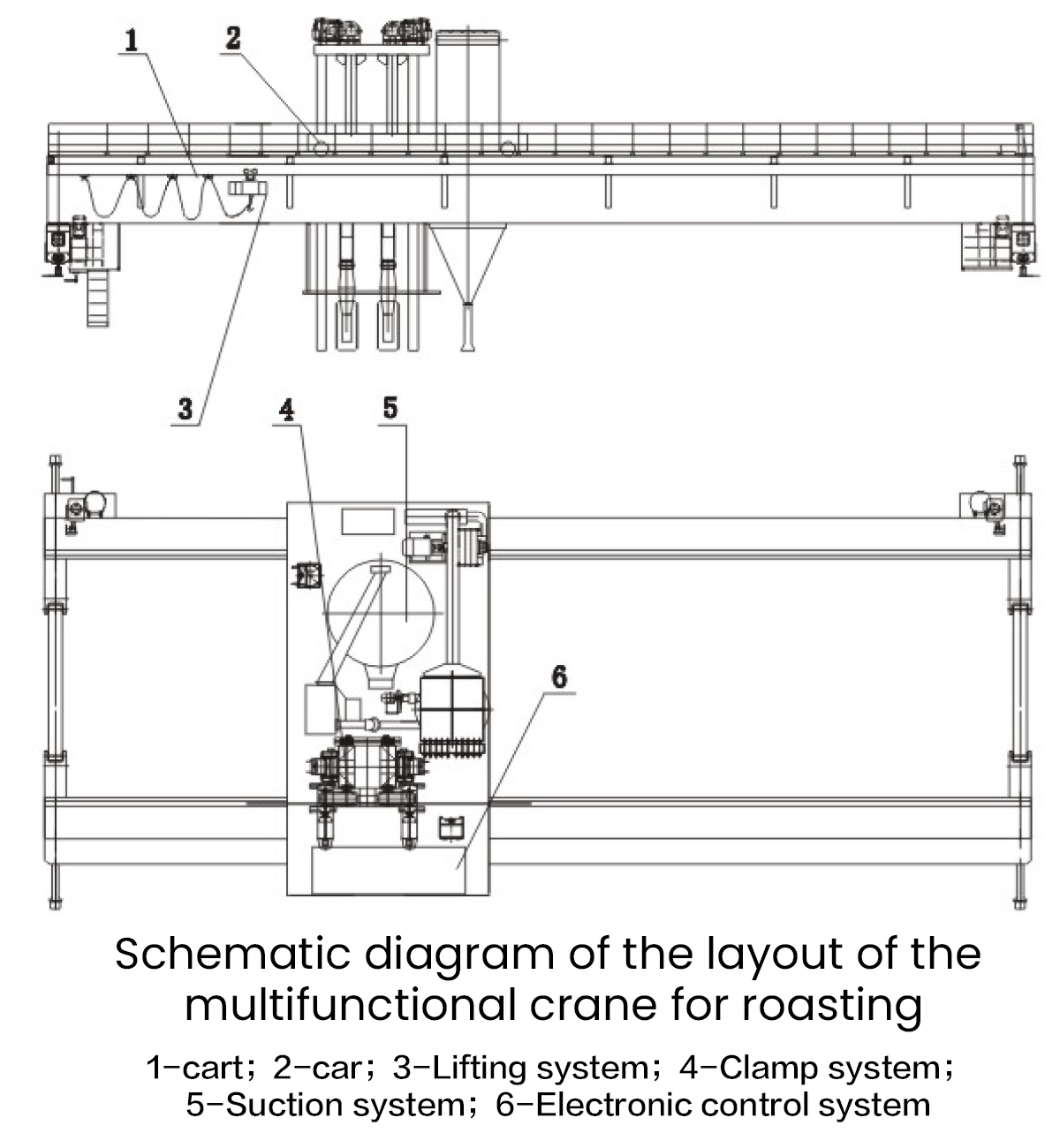

Roasting Multi-Function Crane is a specialized overhead crane designed for the handling and transportation of anode carbon in the aluminum smelting industry. It is an essential equipment used in the production process of aluminum.

The multifunctional roasting crane is a special equipment for the pre-baking anode workshop. Its main process operations:

1. Use clamps to transport the carbon blocks back and forth between the grouping/ungrouping.

2. Use the clamps to load the carbon blocks into/out of the roasting furnace kang.

3. Use the discharge pipe to fill the filling material into the furnace pit.

4. Use the suction pipe to suck out the high-temperature filling material from the furnace pit.

5. There is an electric hoist under the bridge to assist in lifting.

The whole machine adopts PLC control, frequency conversion speed regulation and other configurations. It has been widely used in major carbon factories across the country and has reached the international advanced level. It has greatly improved the harsh working environment and reduced the labor intensity of workers.

| Structure | Ltemized name | Unit | Parameter |

| Complete vehicle | Total weight | t | 180-220 |

| Working level | A6-A8 | ||

| Total installed power | kw | 220-340 | |

| Cart | Running speed | m/min | 5-50 |

| Speed mode | Frequency conversion | ||

| Working level | M6-M8 | ||

| Span | m | 22.5-36 | |

| Car | Running speed | m/min | 3-30 |

| Speed mode | Frequency conversion | ||

| Working level | M6-M8 | ||

| Hoist mechanism | Lifting speed | m/min | 2-8 |

| Speed mode | Frequency conversion | ||

| Working level | M6-M8 | ||

| Lifting capacity of single clamp (excluding clamp) | t | 6-10 | |

| Clamp lifting stroke | m | 7-9 | |

| Suction and discharge system | Suction and discharge pipe lifting speed | m/min | 1.6-16 |

| Suction and discharge pipe lifting stroke | m | 6-10 | |

| Silo | Silo volume | m³ | 10-60 |

| Suction and discharge speed | m³/h | 30-100/65-100 | |

| Cooler | Output temperature | ℃ | ≤80 |

| Cooling area | m³ | 200-600 | |

| Processing temperature | ℃ | 240-600 | |

| Dust collector | Filter area | m³ | 60-200 |

| Filter effect | mg/m³ | ≤15 | |

| Centrifuge | Power | kw | 90-200 |

| Air volume | m³/min | 90-220 | |

| Vacuum degree | kpa | -35 | |

| Air compressor | Pressure | mpa | 0.8 |

| Electric hoist | Lifting capacity | t | 5-10 |

| Lifting speed | m/min | 7-8 | |

| Running speed | m/min | 20 |

OUR FACTORY